English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  ภาษาไทย

ภาษาไทย

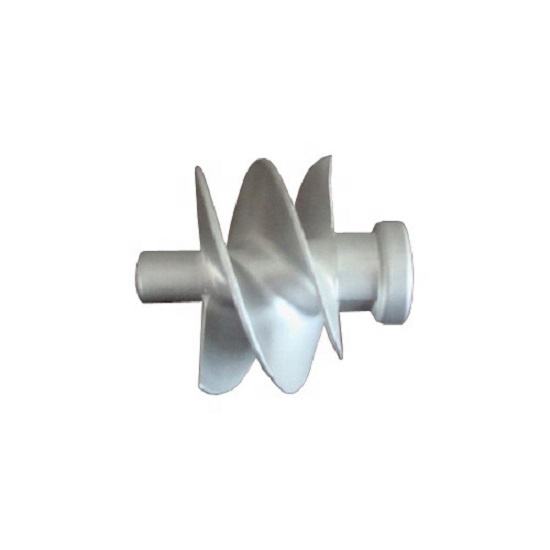

Aluminum Alloy Die Casting Auto Spare Parts

As the professional manufacture, we would like to provide you Aluminum Alloy Die Casting Auto Spare Parts.

Model Number:Non-standards

process:investment casting

material:Steel

Service:Casting and machining

size:as customer's drawings or samples

process:investment casting

material:Steel

Service:Casting and machining

size:as customer's drawings or samples

Send Inquiry

Product Description

Aluminum Alloy Die Casting Auto Spare Parts

Fumin Aluminum alloy die casting is a manufacturing process used to produce auto spare parts made of aluminum alloy. It involves injecting molten aluminum alloy into a custom-designed mold, also known as a die, under high pressure. Once the molten metal solidifies, the mold is opened, and the finished part is ejected.

Here are some key points about aluminum alloy die casting auto spare parts:

Lightweight and High Strength: Aluminum alloy is lightweight yet offers excellent strength and durability, making it suitable for automotive applications. Die-cast aluminum auto spare parts help reduce the overall weight of the vehicle, improving fuel efficiency and performance.

Complex Shapes and Design Flexibility: Die casting allows for the production of auto spare parts with intricate and complex shapes. The mold can be designed to incorporate various features and details, such as ribs, bosses, and thin-walled sections, providing design flexibility for automotive components.

Excellent Surface Finish: Aluminum alloy die-cast parts have a smooth surface finish, which is desirable for automotive applications. They can be further finished through processes like polishing, machining, or coating to achieve the desired appearance and functionality.

Dimensional Accuracy and Tight Tolerances: Aluminum alloy die casting offers high dimensional accuracy and tight tolerances, ensuring precise and consistent production of auto spare parts. This is important for proper fitment and compatibility with other vehicle components.

Heat Dissipation: Aluminum alloys have good thermal conductivity, making them suitable for parts that require heat dissipation, such as engine components, heat sinks, and transmission parts. Die-cast aluminum auto spare parts help in efficient heat management and performance optimization.

Corrosion Resistance: Aluminum alloys used in die casting are inherently corrosion-resistant, providing protection against environmental factors, moisture, and chemicals. This corrosion resistance contributes to the longevity and reliability of auto spare parts, especially in challenging operating conditions.

Cost-Effective Production: Aluminum alloy die casting offers a cost-effective production method for auto spare parts. The high production efficiency, repeatability, and relatively low tooling costs make it a preferred choice for large-scale manufacturing.

Common examples of aluminum alloy die-cast auto spare parts include engine components (such as cylinder heads, engine blocks, and oil pans), transmission housings, suspension components, brackets, and various interior and exterior trim pieces.

It is important to note that the design and production of aluminum alloy die-cast auto spare parts require expertise in tooling design, material selection, and manufacturing processes. Working with experienced manufacturers and ensuring adherence to quality control standards is crucial to ensure the production of high-quality and reliable auto spare parts.

Here are some key points about aluminum alloy die casting auto spare parts:

Lightweight and High Strength: Aluminum alloy is lightweight yet offers excellent strength and durability, making it suitable for automotive applications. Die-cast aluminum auto spare parts help reduce the overall weight of the vehicle, improving fuel efficiency and performance.

Complex Shapes and Design Flexibility: Die casting allows for the production of auto spare parts with intricate and complex shapes. The mold can be designed to incorporate various features and details, such as ribs, bosses, and thin-walled sections, providing design flexibility for automotive components.

Excellent Surface Finish: Aluminum alloy die-cast parts have a smooth surface finish, which is desirable for automotive applications. They can be further finished through processes like polishing, machining, or coating to achieve the desired appearance and functionality.

Dimensional Accuracy and Tight Tolerances: Aluminum alloy die casting offers high dimensional accuracy and tight tolerances, ensuring precise and consistent production of auto spare parts. This is important for proper fitment and compatibility with other vehicle components.

Heat Dissipation: Aluminum alloys have good thermal conductivity, making them suitable for parts that require heat dissipation, such as engine components, heat sinks, and transmission parts. Die-cast aluminum auto spare parts help in efficient heat management and performance optimization.

Corrosion Resistance: Aluminum alloys used in die casting are inherently corrosion-resistant, providing protection against environmental factors, moisture, and chemicals. This corrosion resistance contributes to the longevity and reliability of auto spare parts, especially in challenging operating conditions.

Cost-Effective Production: Aluminum alloy die casting offers a cost-effective production method for auto spare parts. The high production efficiency, repeatability, and relatively low tooling costs make it a preferred choice for large-scale manufacturing.

Common examples of aluminum alloy die-cast auto spare parts include engine components (such as cylinder heads, engine blocks, and oil pans), transmission housings, suspension components, brackets, and various interior and exterior trim pieces.

It is important to note that the design and production of aluminum alloy die-cast auto spare parts require expertise in tooling design, material selection, and manufacturing processes. Working with experienced manufacturers and ensuring adherence to quality control standards is crucial to ensure the production of high-quality and reliable auto spare parts.

Our factory supply OEM service(custom service) in precision investment casting,which are also called lost wax casting, We have been committed to this technique for over 10 years . Our specialized engineer can provide you the full-service of technology advice and products improving projection,and also reduce the cost of the parts.

|

Investment casting (lost wax casting) |

Stainless steel casting Alloy steel casting Carbon steel casting Bronze and Brass casting Aluminum casting |

| Machining |

Drilling, Reaming and tapping CNC Turning machining CNC Milling machining Wire EDM |

| Heat treatment |

Annealing Solution Normalizing Tempering Quenching Induction hardening Hardening and tempering |

| Surface treatment |

Manual polishing Electro-polishing Electro-plating Power coating Tumbling |

| Process | Investment casting Shell mold casting Lost wax casting |

| Processing Ability | Surface finishment: Ra1.6-Ra3.2 |

| Size tolerance: VDG P690 D2 | |

| Maximum size: ≤1200mm×800mm×400mm | |

| Weight range: 0.1Kg-120Kg | |

| Material |

stainless steel, carbon steel, alloy steel, heat-resistant steel, hardend steel,mild steel |

|

Brass CuZn38,H62 Aluminum bronze AB2,863 |

|

| Cast aluminium alloy ZL101,ZL114A,A356 | |

| Application |

Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts pump & valve parts and accessories Impellers and propellers(propellors) Pipe Fittings or pipeline accessories Other industry metal casting parts |

| Design | Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

| Standards | AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

| Inspection |

Dimension inspection Chemical composition analysis (Spectrum analysis) Mechanical property testing X-Ray inspection Dye penetrant inspection Magnetic powder inspection Metallographic inspections |

Hot Tags: Aluminum Alloy Die Casting Auto Spare Parts, Manufacturers, Suppliers, China, Factory, Free Sample, Low price, Quality, Customized

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy