English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик  ภาษาไทย

ภาษาไทย

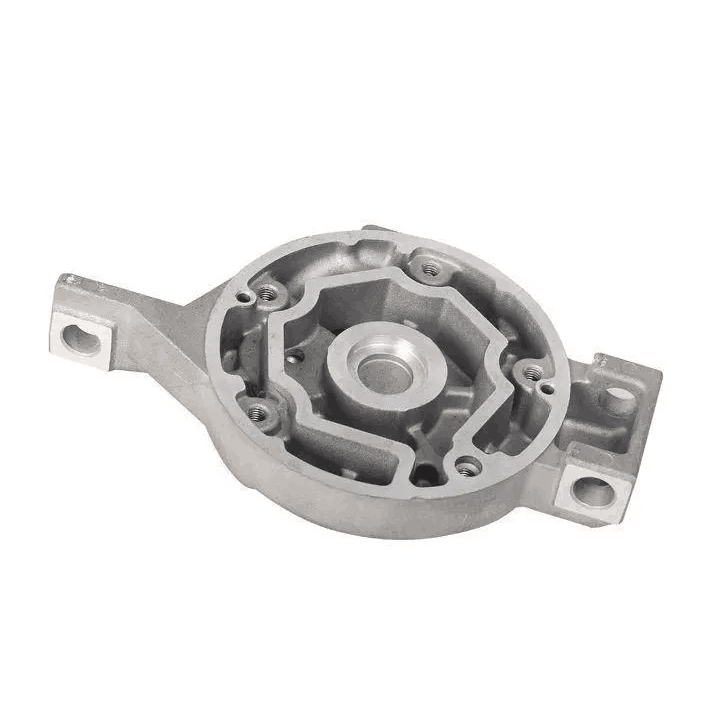

Motorcycle Automotive Auto Aluminum Casting Parts

The following is the introduction of high quality Motorcycle Automotive Auto Aluminum Casting Parts, hoping to help you better understand Motorcycle Automotive Auto Aluminum Casting Parts. Welcome new and old customers to continue to cooperate with us to create a better future!

Model Number:customized OEM

Material:Iron

Certification:IATF16949

Service:OEM ODM Customised

Process:Casting +Machining(if Need)+surface Treatmen

Material:Iron

Certification:IATF16949

Service:OEM ODM Customised

Process:Casting +Machining(if Need)+surface Treatmen

Send Inquiry

Product Description

Motorcycle Automotive Auto Aluminum Casting Parts

Fumin Motorcycle Automotive Auto Aluminum Casting Parts offer several advantages, including lightweight construction, durability, and design flexibility. Here are some key points about aluminum casting parts for motorcycles and automotive vehicles:

Lightweight Construction: Aluminum is known for its lightweight properties, making it an ideal material for motorcycle and automotive parts. Aluminum casting allows for the creation of lightweight components that contribute to improved fuel efficiency, handling, and overall performance of the vehicle.

Strength and Durability: Despite being lightweight, aluminum casting parts offer high strength and durability. The casting process ensures that the parts have the necessary structural integrity and can withstand the rigors of motorcycle and automotive applications.

Design Flexibility: Aluminum casting enables the production of complex shapes and intricate designs that may be difficult or costly to achieve with other manufacturing methods. This design flexibility allows for the creation of efficient and optimized components that meet the specific requirements of motorcycles and automotive vehicles.

Heat Dissipation: Aluminum has excellent thermal conductivity, meaning it effectively dissipates heat. This property is beneficial for parts that are exposed to high temperatures, such as engine components or braking systems. Aluminum casting parts help dissipate heat quickly, enhancing the overall performance and longevity of the motorcycle or vehicle.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing resistance against corrosion. This makes aluminum casting parts suitable for outdoor and harsh environments, where exposure to moisture and other corrosive elements is common.

Cost-Effectiveness: Aluminum casting is a cost-effective manufacturing process, especially for producing complex or customized parts. The ability to produce intricate designs in a single piece reduces the need for assembly or additional machining operations, resulting in cost savings during production.

Wide Range of Applications: Aluminum casting parts are used in various motorcycle and automotive applications, including engine components (cylinder heads, engine blocks, intake manifolds), transmission cases, wheel hubs, suspension components, and various exterior and interior parts.

Surface Finish and Aesthetics: Aluminum casting parts can be finished to achieve the desired surface texture and aesthetics. Surface treatments such as polishing, painting, anodizing, or powder coating can be applied to enhance the appearance and protect the parts from environmental factors.

When manufacturing aluminum casting parts for motorcycles and automotive vehicles, it is important to work with experienced foundries or manufacturers that specialize in aluminum casting. This ensures the use of high-quality materials, precise casting techniques, and adherence to industry standards and specifications.

Overall, aluminum casting provides an excellent solution for producing lightweight, durable, and high-performance parts for motorcycles and automotive vehicles. The combination of strength, design flexibility, and cost-effectiveness makes aluminum casting an attractive choice for manufacturers in the industry.

Lightweight Construction: Aluminum is known for its lightweight properties, making it an ideal material for motorcycle and automotive parts. Aluminum casting allows for the creation of lightweight components that contribute to improved fuel efficiency, handling, and overall performance of the vehicle.

Strength and Durability: Despite being lightweight, aluminum casting parts offer high strength and durability. The casting process ensures that the parts have the necessary structural integrity and can withstand the rigors of motorcycle and automotive applications.

Design Flexibility: Aluminum casting enables the production of complex shapes and intricate designs that may be difficult or costly to achieve with other manufacturing methods. This design flexibility allows for the creation of efficient and optimized components that meet the specific requirements of motorcycles and automotive vehicles.

Heat Dissipation: Aluminum has excellent thermal conductivity, meaning it effectively dissipates heat. This property is beneficial for parts that are exposed to high temperatures, such as engine components or braking systems. Aluminum casting parts help dissipate heat quickly, enhancing the overall performance and longevity of the motorcycle or vehicle.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing resistance against corrosion. This makes aluminum casting parts suitable for outdoor and harsh environments, where exposure to moisture and other corrosive elements is common.

Cost-Effectiveness: Aluminum casting is a cost-effective manufacturing process, especially for producing complex or customized parts. The ability to produce intricate designs in a single piece reduces the need for assembly or additional machining operations, resulting in cost savings during production.

Wide Range of Applications: Aluminum casting parts are used in various motorcycle and automotive applications, including engine components (cylinder heads, engine blocks, intake manifolds), transmission cases, wheel hubs, suspension components, and various exterior and interior parts.

Surface Finish and Aesthetics: Aluminum casting parts can be finished to achieve the desired surface texture and aesthetics. Surface treatments such as polishing, painting, anodizing, or powder coating can be applied to enhance the appearance and protect the parts from environmental factors.

When manufacturing aluminum casting parts for motorcycles and automotive vehicles, it is important to work with experienced foundries or manufacturers that specialize in aluminum casting. This ensures the use of high-quality materials, precise casting techniques, and adherence to industry standards and specifications.

Overall, aluminum casting provides an excellent solution for producing lightweight, durable, and high-performance parts for motorcycles and automotive vehicles. The combination of strength, design flexibility, and cost-effectiveness makes aluminum casting an attractive choice for manufacturers in the industry.

| Processes | Material Available Sand Casting |

| Material Available | Ductile Iron, Steel |

| Weight range | 5~100kgs |

OEM & ODM

We provide OEM and ODM services. At the same time, we optimize according to the requirements of technology and cost, so that customers can get more cost-effective products.

Strict Process Control

Follow quality management procedures such as ISO9001,TS16949

Our ablity

We have 10years' experiences in the design and manufacture of industrial parts.

Strict Process Control

Follow quality management procedures such as ISO9001,TS16949

Our ablity

We have 10years' experiences in the design and manufacture of industrial parts.

Hot Tags: Motorcycle Automotive Auto Aluminum Casting Parts, Manufacturers, Suppliers, China, Factory, Free Sample, Low price, Quality, Customized

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy